- JA Solar

- Nikon

- 3D Print Bureau

- 6K

- Agmatix

- Airwayz

- AKA Foods

- AM-Flow

- Appadda

- Caracol

- Carbon

- CG Trader

- Conflux

- CyberOptics

- e-Xstream

- Flamerite

- GenCell

- GreenEye

- Impossible Objects

- Incus Media

- Ineco

- InkBit

- ITG

- JPB Systeme

- KeyProd

- Landa

- LEO Lane

- Lumet

- Magic Software

- MakerBot

- Marketiger

- Nano Dimension

- Paragon Rapid Technologies

- PearlX

- Plant & Bean

- Redefine Meat

- Replique

- Ripples

- Sakuu Corporation

- Segen

- SolarEdge

- StoreDot

- Sunrock

- The Bespoke Group

- Trigo

- UltiMaker

- Xjet

Qcells – First to Deploy Disruptive Lumet Fine-Line Metallization Technology for its PV Solar Cell Lines

Qcells, one of the world’s leading clean energy companies, and Lumet, producer of ultrafine-line metallization systems, today announced that Qcells will become the world’s first PV solar company to deploy Lumet’s disruptive fine-line metallization technology for its PV solar cell lines. Qcells currently operates the largest solar module factory of its kind in the United States and has announced the largest investment in U.S. solar history to build a complete and sustainable solar supply chain in America.

The explosive adoption of solar power around the world has been driven by society’s need to replace its dependence on fossil fuels with clean renewable energy. Today, solar is the fastest growing – and lowest cost – power source on the planet, a result of the industry’s relentless quest to enhance solar cell efficiency and lower production costs.

The single largest cost of solar cell production is the metallization step, in which conductive silver fingers (collectors) are screen-printed onto the cell’s surface. The industry has long sought to reduce finger width, in order to both decrease silver consumption (lower cost) and reduce light shading (increase efficiency). However, screen printing technologies have now plateaued at finger widths of about twenty microns and are thus unable to deliver the efficiency and cost improvements sought by the industry.

Lumet fine-line metallization technology, capable of producing even sub-ten-micron finger widths, will enable PV solar cell producers to now attain both higher cell efficiency and lower cost.

“After lengthy evaluation and testing, Qcells has decided to adopt Lumet metallization technology for its future PV solar cell lines,” stated Dr. Danielle Merfeld, EVP and Global Chief Technology Officer at Qcells. “We see tremendous potential in the Lumet metallization technology, which is a breakthrough on multiple fronts, setting records for finest lines, lowest cost, highest efficiency, highest speed and smallest footprint. Moreover, with Qcells’ commitment to expanding our USA-based manufacturing, the low CAPEX and high automation level of the Lumet systems are very attractive. For all those reasons, we are thrilled that Qcells will be the first to introduce this technology to the market and we look forward to taking further steps to deepening our strategic partnership with Lumet.”

Lumet Founder and Chairman, Benny Landa, added: “We are delighted to partner with Qcells and look forward to collaboratively bringing Lumet technology to the mass production PV solar market. Qcells has a rich history of pioneering and innovation. Not only is Qcells one of the world’s first solar pioneers, it was also the first to reach gigawatt-scale production – and to this day continues to be at the forefront of innovation, most recently with its introduction of LECO (Laser Enhanced Contact Optimization) technology. And now it is bringing the benefits of Lumet technology to the PV solar market – another first for Qcells! That’s very exciting news, both for us and for the PV solar industry!”

Dr. Merfeld concluded: “Innovation and clean energy technology are going to be critical to cutting global emissions and developing low cost, accessible, reliable energy for communities around the world. That’s our mission. Today, in partnership with Lumet, we are taking an important step towards reaching that goal.”

-

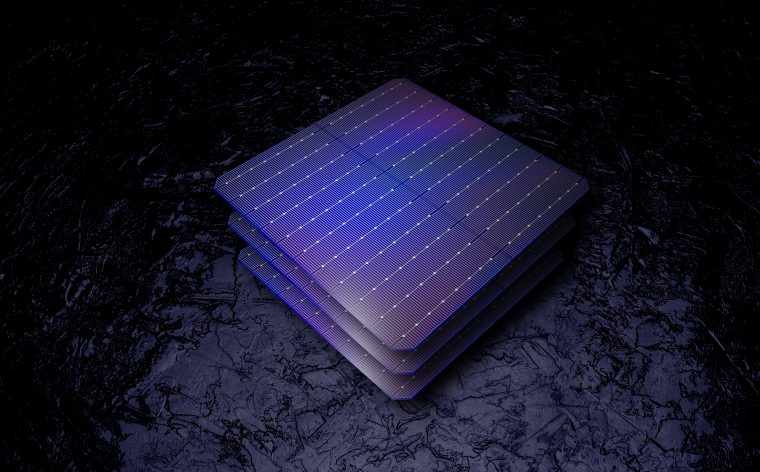

Lumet-metallized silicon solar cells

Lumet-metallized silicon solar cells

Click here to download 300dpi images -

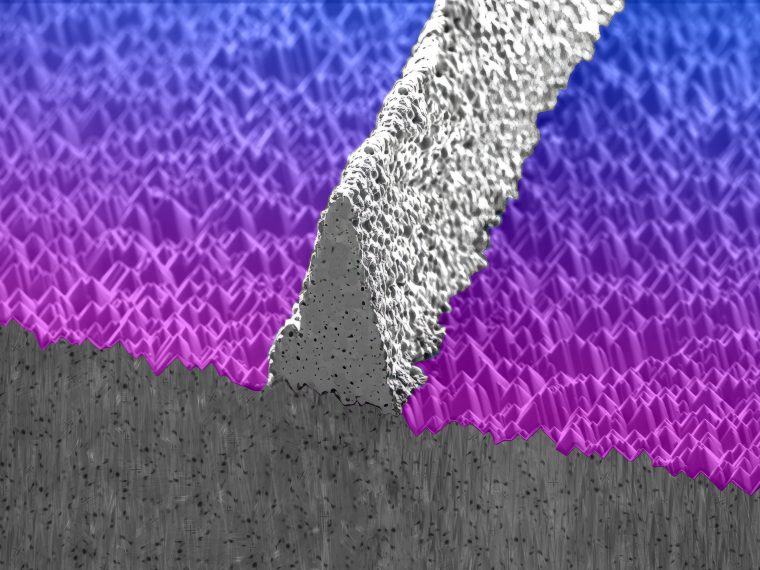

Lumet finger on silicon solar cell, capable of reaching 5 micron width compared to 20 micron available today in the solar industry

Lumet finger on silicon solar cell, capable of reaching 5 micron width compared to 20 micron available today in the solar industry

Click here to download 300dpi images -

Qcells to adopt Lumet metallization technology in its future solar cell lines

Qcells to adopt Lumet metallization technology in its future solar cell lines

Click here to download 300dpi images